Experiential Learning (ExL) – Fabrication / Model Development

“You never change things by fighting the existing reality. To change something, build a new model that makes the existing model obsolete.”

— Buckminster Fuller

Preamble:

To acquire technological “literacy”, students must be given the opportunity to actively participate in the solution of technical problems. This course would help students to learn application of different tools, equipment & machineries used in fabrication of process equipment and various fabrication works in deferent engineering application.

Introduction:

Industry serves the society by offering products & services to the customers. To Identify the customer needs, converts them to drawing and to parts to serve them along with Machines, Materials & Equipment, it also require Trained/ Skilled people for operations to make the parts. This course introduces key concepts, processes and principles of industry driven digital fabrication in a manufacturing environment. Students will undertake small-scale, team-based project work to create fabricated objects that relate to a local industry, organisation or community need or opportunity. the fabrication process end-to-end, analyse outputs and finished products, and evaluate their conformance to requirements.

Course Objectives:

The students will try to learn:

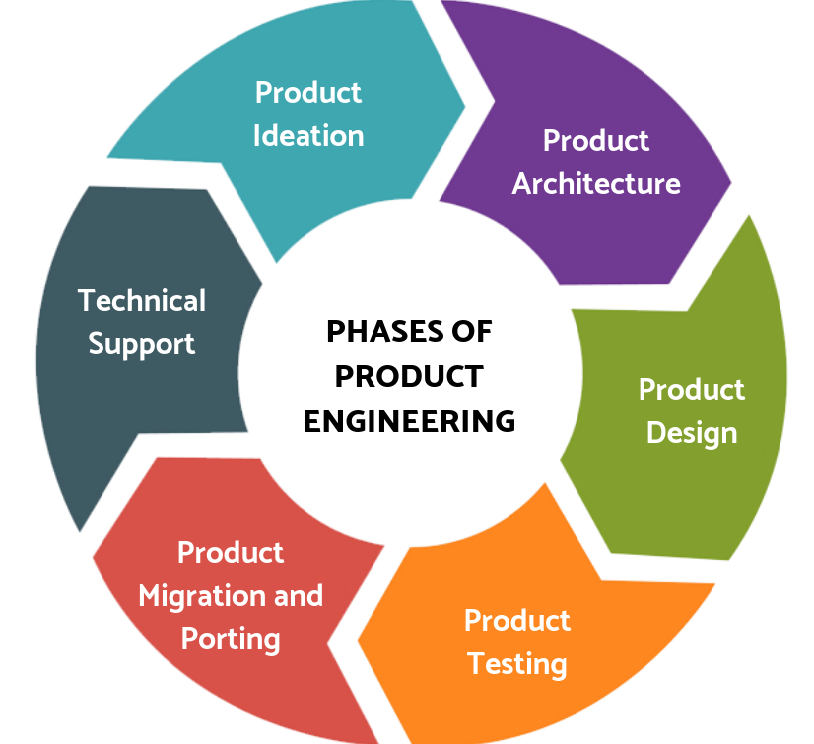

- The basic knowledge of fabricating the models from its prototyping versions.

- The modeling, programming and operations of machinery required for fabrication of components / models.

- The applications of engineering domains and utilize the knowledge for creating new products / processes and services

Course Outcomes:

Students will be able to

- Apply the knowledge of innovation and creativity to develop new models.

- Identify the various machinery and tools required for modeling and fabrication.

- Choose appropriate techniques to improve the technology readiness levels of models.

- Conduct design studies to identify a technological solution to a problem.

- Create the solutions to the real world identified problems.

Mapping of CO and PO:

| |

Course Outcomes |

Program Outcomes |

| CO1 |

Apply the knowledge of innovation and creativity to develop new models |

PO3, PO4 |

| CO2 |

Identify the various machinery and tools required for modeling and fabrication |

PO1, PO5 |

| CO3 |

Choose appropriate techniques to improve the technology readiness levels of models |

PO3, PO4, PO5, PO9, PO10 |

| CO4 |

Conduct design studies to identify a technological solution to a problem |

PO4, PO5, PO9, PO10 |

| CO5 |

Create the solutions to the real world identified problems |

PO3, PO4, PO5, PO9, PO10 |

Evaluation and Continuous Assessment:

The course is worth one credit hour with the contact time hundred minute session per week. All the sessions in every week is used for familiarization on machinery and equipment, tools, software’s, materials and other processes used in modeling and fabrication of innovative products. It is recommended that the all activities are to be record on regular basis and proper documents are to be maintained by students and faculty mentor. The final assessment of course includes the demonstration of POC model and its higher technology readiness level (TRL) models and report submission.

Process:

Work with Us

Work with Us Campus Map

Campus Map How to Reach Us

How to Reach Us Online Degree Verification

Online Degree Verification Photo Gallery

Photo Gallery